SKI CORES:

heart of the matter

by Ian March from Buyer’s Guide 2010 issue

With skis, just as in love, we are often initially drawn to our mate by what’s on the

surface. But, as your parents should have told you, for true happiness, it’s what’s

inside that counts.

To avoid a broken heart, let’s go beneath the surface, right to the core. The personality and feel of a ski is the result of a combination of construction materials, construction methods and dimensions. If two or more manufacturers made skis with the exact same dimensions, they can still feel very different on snow, but for this discussion let’s take dimensions out of the equation. So what makes the difference? Likely the largest contributor to the ski’s feel is the core, mostly what it’s made of and also how it’s put together. The core influences such important factors as a ski’s weight, dampness (ability to absorb vibration), stability, responsiveness and energy. The following are some generalizations to keep in mind on ski cores, their construction and characteristics.

CORE MATERIALS

WOOD: Heavier, stable, damp, responsive,

durable and solid-feeling with consistent flex.

INJECTED FOAM: Light, quick-feeling, less

stable than other cores, but also less expensive

to produce.

FOAM (milled or cut from a block): Light,

energetic feel; generally less damp and less

stable than wood; more consistent flex than

injected foam; and generally between injected

foam and wood in terms of cost.

LAMINATE: Layers of materials bonded together

using epoxy, heat and pressure. Various types

of wood or foam can be laminated to create

a ski’s core, e.g. using a centre of birch (for

strength) with balsa bonded to it will produce a

lightweight core that absorbs vibration well.

CONSTRUCTION

But wait! Again, just as in love, it’s not that

simple. Let’s not forget construction. The

construction surrounding the core works with

the core’s characteristics to ultimately finetune

the feel and capability of the ski. There

are three main construction techniques in

today’s skis, each offering its own unique

benefits and tradeoffs.

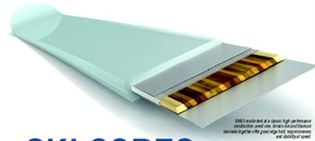

Völkl’s inside look at a classic high-performance

construction: wood core, torsion box and titanium

laminate together offer great edge hold, responsiveness

and stability at speed.

TORSION BOX: Fibreglass layers wrapped

around the core add torsional stiffness

to a ski, resulting in excellent edge hold,

consistent flex and durability. Torsion-box

construction generally results in a more

demanding ski to use. Stronger skiers take

note, a large number of race skis at the World

Cup level, as well as many higher-end freeride

skis, use torsion-box construction.

SANDWICH: Various laminates (metal,

titanium, fibreglass) layer along the top

or bottom of the core to alter flex and

dampness. For example, adding a layer of

metal can add weight (yes, this can be a good

thing), stability and vibration absorption

(dampness).

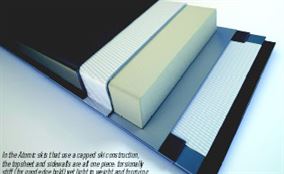

In the Atomic skis that use a capped ski construction,

the topsheet and sidewalls are all one piece: torsionally

stiff (for good edge hold) yet light in weight and forgiving.

CAPPED: In the case of capped or monocoque construction, the topsheet and sidewalls are formed as one piece, like a cap that surrounds the ski. The cap bears the load of the ski. While the cap adds to torsional stiffness, at the same time it allows the ski to be light in weight and softer overall (longitudinally), resulting in a more forgiving ski that still has good edge hold—a very good thing for aspiring skiers who spend a lot of time on eastern hardpack.

CHARACTERISTICS

So what does all of this mean? What about

me and my search for the perfect mate? Easy

there, Romeo, use your head here. Keep these

core and construction characteristics in mind

when thinking about what you’re looking for

(in a ski!) and what “feel” you like:

• Do you like a light, quick ski? Are you

less concerned about stability at speed? A

foam core might generally keep the quick

and nimble happy.• Do you like to blast through everything,

moguls and crud exploding beneath your

feet? Maybe the solid feel and durability

of wood is up your alley.• Do you need or simply like a forgiving

ski, but get nervous on hard snow and

ice? Capped construction can offer both

forgiveness and good edge hold.• Do you aspire to race on the World Cup

or at least beat your friends in the gates?

The awesome edge hold of a torsion box,

the dampening of a wood core and a

metal layer just might be your ticket to

the podium.

If you still have cold feet and are

not sure, other questions you could ask

yourself are: What factors took a ski

experience from the competent to the

sublime, and what in the ski helped make

it so? Was it the ski’s solid feeling that

gave you con?dence and enabled you to

push yourself to new limits? The quick,

snappy, light feeling that made you dance

through that mogul ?eld? Or was it the

splashy graphics that look so…wait! If

this is you, then please return to the

beginning and start reading again.

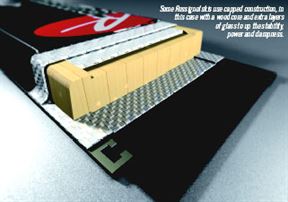

Some Rossignol skis use capped construction, in

this case with a wood core and extra layers

of glass to up the stability,

power

One caveat: Remember that the

characteristics we have been discussing

are generalizations. There is no substitute

for actually trying a ski on snow. And when

you do get the opportunity to demo some

skis, ask the rep what’s inside and then see

if you can feel the characteristics while

ripping up the mountain. You’ll likely use

your demo time more effectively now that

you’re an expert on core construction. And

don’t forget the old adage when searching

for the perfect mate for the slopes: beauty

is in the eye of the beholder.